TRITAN™

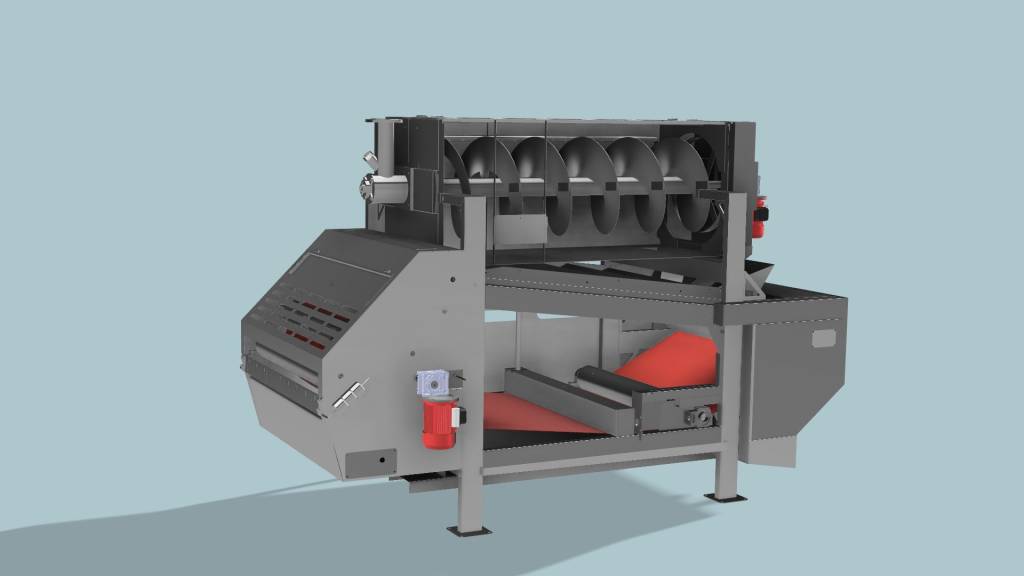

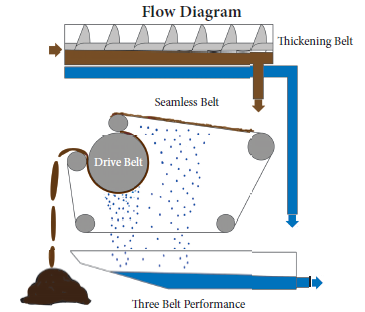

The TRITAN™ belt filter press is a new design. The stainless steel TRITAN™ combines a sludge pre-thickener and a sludge press into one unit, eliminating the need for two separate pieces of equipment. It has three belt performances with single belt tracking.

With few moving parts, the belt press design lends itself to minimal maintenance. It utilizes seamless belt technology for long life, while providing excellent dewatering and a dry cake equal to traditional equipment. The TRITAN™ produces a bio-solids cake with a solids concentration of 12% to 16% for aerobic sludge, and higher for anaerobic sludge.

- Simplicity

- Compact Design

- Economical Solution

- Pre-Thickening

- Performance

- Packaged & Integrated Solution

- Stainless Steel

Rotary Drum Thickener

The Rotary Drum Thickener is the most economical and modern solution to sludge thickening. It can be used in a variety of thickening applications, such as:

Condensing sludge prior to dewatering

Prior to biogas reactors; thus, enabling smaller bioreactors

Prior to long term storage (such as winter storage for summer agriculture application)

Prior to applying to drying beds or agricultural lands; thus, reducing space requirements

Removal of coarse materials (such as fibers in the textile industry)

Advantages of the Rotary Drum Solution

The principal advantage of the Rotary Drum Thickener is the use of an Archimedean screw instead of the conventional drum filter. The polyester filter cloth is fixed to the Archimedean screw, making a drum with a screw inside. The drum filter is rotated by an adjustable gearmotor. This design enables an easy and simple control of the dewatering process by adjusting the rotation speed to achieve the optimal dewatering time and preventing short-circuiting.

The achievable dewatering results are much higher than with conventional systems. The filter cloth is kept clean by making use of washing water at high pressure from outside. The filter cloth has a long life, since it is not under tensile stress. The Rotary Drum Thickener is supplied complete with control panel, washing pump and all the ancillary equipment necessary for efficient operation.

The Rotary Drum Thickener can handle from 10 gpm to a maximum of 250 gpm, depending upon the type of sludge and the dry solid content. Changing the speed of the Archimedean screw allows adjustment of the concentration of the thickened sludge and minimizes the use of Polyelectrolyte. As a general guide, sludge with 0.5 – 3% can be thickened to 6 – 9% Dry Solids. As with other equipment by Aero-Mod, Rotary Drum Thickener is manufactured with AISI 304 Stainless Steel.